- Introduction to laser cleaning technology

- The importance of maintaining clean industrial machinery

- Cost-effectiveness of laser cleaning in industrial settings

- Training and certification for laser cleaning operators

- The future of laser cleaning technology in the industrial sector

- Case studies of improved product quality due to laser cleaning

- The environmental impact of using laser cleaning technology

- The impact of laser cleaning on reducing waste and environmental footprint

Introduction to laser cleaning technology

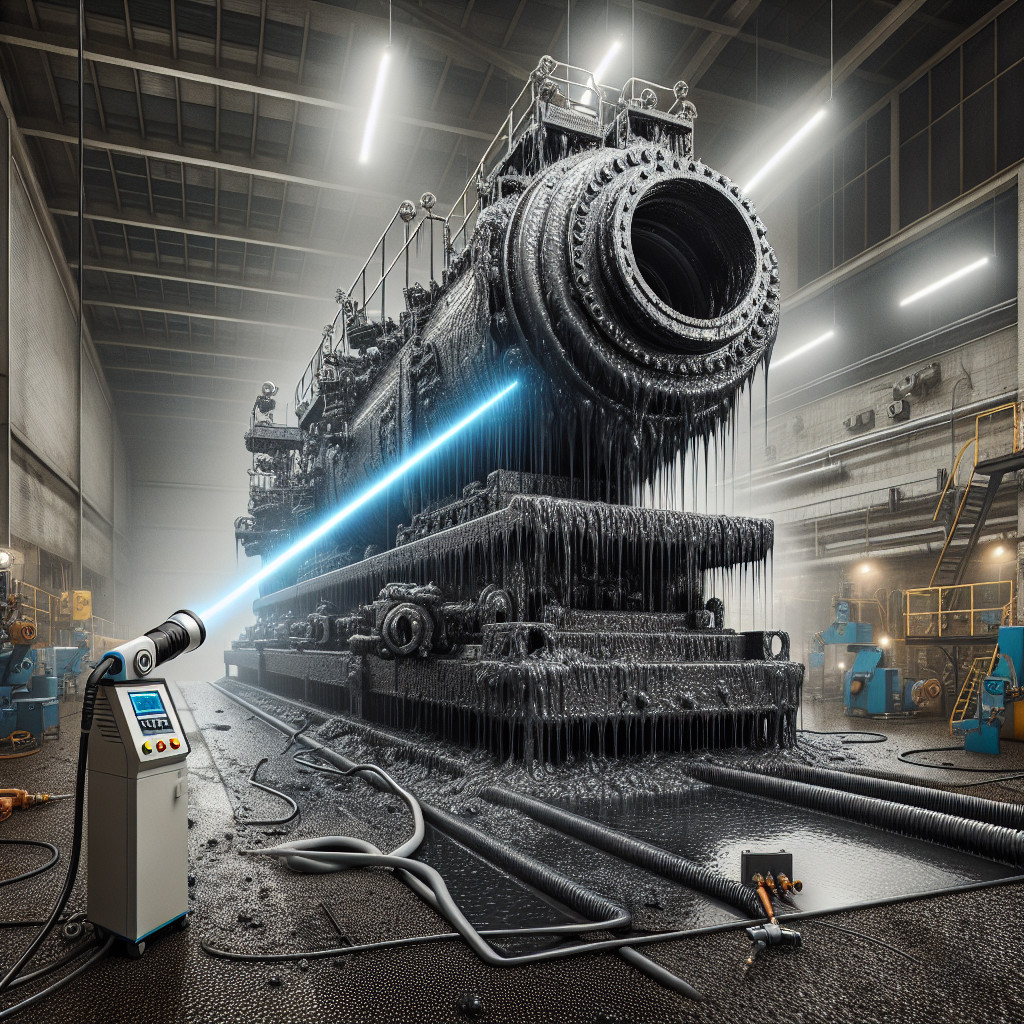

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, and oxides from various surfaces. This innovative technique utilizes the power of laser beams to vaporize unwanted substances without causing damage to the underlying material. Laser cleaning is becoming increasingly popular in industries such as automotive, aerospace, and electronics due to its efficiency and precision.

How does laser cleaning work?

Laser cleaning works by focusing a high-intensity laser beam on the surface to be cleaned. The energy from the laser beam is absorbed by the contaminants, causing them to vaporize and be removed from the surface. The laser beam can be adjusted to different wavelengths and intensities depending on the type of material being cleaned. This allows for precise control over the cleaning process and ensures that only the contaminants are removed, leaving the underlying material unharmed.

Benefits of laser cleaning technology

– Non-contact cleaning: Laser cleaning does not require physical contact with the surface, reducing the risk of damage or contamination.

– Environmentally friendly: Laser cleaning does not produce any waste or harmful byproducts, making it a sustainable cleaning solution.

– Versatile: Laser cleaning can be used on a wide range of materials, including metals, plastics, and ceramics.

– Cost-effective: Laser cleaning is a cost-effective solution compared to traditional cleaning methods, as it requires less time and labor.

🔹Applications of laser cleaning technology🔹

– Rust removal: Laser cleaning can effectively remove rust from metal surfaces without damaging the underlying material.

– Paint stripping: Laser cleaning is used to strip paint from surfaces such as cars, aircraft, and buildings.

– Surface preparation: Laser cleaning can be used to prepare surfaces for painting, welding, or bonding by removing contaminants and oxides.

Overall, laser cleaning technology offers a fast, efficient, and environmentally friendly solution for removing contaminants from various surfaces. Its versatility and precision make it an ideal choice for industries looking to improve their cleaning processes.

#laser #cleaning #technology

Keywords: laser cleaning, contaminants, precision, efficiency, non-contact cleaning, environmentally friendly, versatile, cost-effective

Long-tail phrases: laser cleaning technology for rust removal, laser cleaning applications in automotive industry, benefits of laser cleaning in aerospace sector.

The importance of maintaining clean industrial machinery

Preventing breakdowns and downtime

One of the main reasons why it is important to keep industrial machinery clean is to prevent breakdowns and downtime. Dirty machinery is more prone to malfunctions and failures, which can lead to costly repairs and production delays. By regularly cleaning and maintaining industrial machinery, businesses can reduce the risk of unexpected breakdowns and keep their operations running smoothly.

Ensuring product quality

Clean machinery is essential for ensuring the quality of the products being manufactured. Dust, dirt, and debris can contaminate products and affect their appearance, performance, and safety. By keeping industrial machinery clean, businesses can maintain high product standards and meet customer expectations.

Improving safety

Dirty machinery can pose safety hazards to workers and increase the risk of accidents in the workplace. Oil spills, debris buildup, and other contaminants can create slippery surfaces and obstruct moving parts, leading to injuries and damage. Regular cleaning and maintenance of industrial machinery are essential for creating a safe working environment for employees.

Extending the lifespan of machinery

Proper maintenance and cleaning can help extend the lifespan of industrial machinery. Regular inspections, lubrication, and cleaning can prevent wear and tear, corrosion, and other forms of damage that can shorten the lifespan of machinery. By investing in maintenance, businesses can prolong the life of their equipment and save money on replacements.

Reducing energy consumption

Clean machinery operates more efficiently and consumes less energy than dirty machinery. Dust and dirt can clog filters, vents, and moving parts, causing machinery to work harder and use more energy. By keeping industrial machinery clean, businesses can reduce their energy consumption and lower their operating costs.

Enhancing productivity

Well-maintained machinery is essential for maximizing productivity in the workplace. Clean machinery operates smoothly, reliably, and efficiently, allowing businesses to meet production targets and deadlines. By investing in maintenance and cleaning, businesses can improve their overall productivity and competitiveness in the market.

Conclusion

In conclusion, maintaining clean industrial machinery is essential for businesses to ensure optimal performance, efficiency, and safety. By regularly cleaning and maintaining machinery, businesses can prevent breakdowns, ensure product quality, improve safety, extend the lifespan of equipment, reduce energy consumption, and enhance productivity. Investing in maintenance is a cost-effective way for businesses to protect their assets, increase their profitability, and stay competitive in the industry.

- Preventing breakdowns and downtime

- Ensuring product quality

- Improving safety

- Extending the lifespan of machinery

- Reducing energy consumption

- Enhancing productivity

#cleanmachinery #industrialmaintenance #productquality #safety #efficiency #energyefficiency #productivity

Cost-effectiveness of laser cleaning in industrial settings

Benefits of laser cleaning

One of the main benefits of laser cleaning is its ability to remove contaminants without the need for harsh chemicals or abrasive materials. This not only reduces the environmental impact of the cleaning process but also eliminates the need for costly disposal of hazardous waste. Additionally, laser cleaning is a non-contact process, which means that it can be used on delicate surfaces without causing damage.

Cost comparison

When comparing the cost of laser cleaning to traditional cleaning methods, it is important to consider the long-term savings that can be achieved. While the initial investment in laser cleaning equipment may be higher than traditional cleaning equipment, the reduced need for consumables and the lower maintenance costs can result in significant savings over time. Additionally, the efficiency of laser cleaning means that less time and labor are required for cleaning tasks, further reducing costs.

Case studies

Several case studies have shown the cost-effectiveness of laser cleaning in industrial settings. For example, a manufacturing plant that switched to laser cleaning reported a 30% reduction in cleaning costs and a 20% increase in productivity. Another study found that a company that used laser cleaning for maintenance tasks saved over $50,000 per year in labor costs alone.

Conclusion

In conclusion, laser cleaning offers a cost-effective and efficient solution for cleaning in industrial settings. While the initial investment may be higher, the long-term savings and increased productivity make it a worthwhile investment for many companies.

| Cost comparison | Laser cleaning | Traditional cleaning |

|---|---|---|

| Initial investment | Higher | Lower |

| Consumables | Less | More |

| Maintenance costs | Lower | Higher |

#laser #cleaning #costeffectiveness #industrial #efficiency

Training and certification for laser cleaning operators

Training for laser cleaning operators

Training for laser cleaning operators typically involves a combination of classroom instruction and hands-on experience. Operators must learn how to safely operate the laser cleaning machine, as well as how to properly set up and maintain the equipment. They must also be trained in laser safety procedures and protocols to prevent accidents and injuries.

Additionally, operators must be familiar with the different types of lasers used in cleaning applications, as well as the specific requirements for each type of surface being cleaned. They must also understand the principles of laser technology and how it interacts with different materials.

Certification for laser cleaning operators

Once operators have completed their training, they must pass a certification exam to demonstrate their knowledge and skills. Certification is typically provided by industry organizations or manufacturers of laser cleaning equipment. It is important for operators to maintain their certification through ongoing training and professional development.

Certification ensures that operators have the necessary skills and knowledge to safely and effectively operate a laser cleaning machine. It also provides a level of assurance to employers and customers that the operator is competent and qualified to perform the job.

Key skills and knowledge for laser cleaning operators

| Skill/Knowledge | Description |

|---|---|

| Laser safety | Understanding of laser safety protocols and procedures |

| Equipment operation | Ability to operate and maintain laser cleaning equipment |

| Surface preparation | Knowledge of surface preparation techniques for different materials |

| Material interaction | Understanding of how lasers interact with different materials |

Conclusion

Training and certification are essential for laser cleaning operators to ensure the safe and effective operation of laser cleaning equipment. By acquiring the necessary skills and knowledge, operators can perform their jobs with confidence and competence, while also providing a high level of service to their employers and customers.

#laser #cleaning #operators #training #certification #safety #skills #knowledge #equipment #technology #industry

frazy kluczowe:

– importance of training and certification for laser cleaning operators

– specialized training for laser cleaning operators

– laser safety procedures and protocols

– principles of laser technology

– certification exam for laser cleaning operators

– ongoing training and professional development

– key skills and knowledge for laser cleaning operators

– surface preparation techniques for different materials

– material interaction with lasers

The future of laser cleaning technology in the industrial sector

Here are some key trends and developments shaping :

1. Advancements in laser technology: With ongoing research and development, laser cleaning technology is becoming more efficient and cost-effective. New laser systems are being developed that can clean a wider range of materials and surfaces, making them suitable for a variety of industrial applications.

2. Integration with automation: Laser cleaning technology is increasingly being integrated with automation systems to improve efficiency and productivity in industrial settings. Automated laser cleaning systems can be programmed to clean specific areas or surfaces without the need for manual intervention.

3. Environmental sustainability: Laser cleaning technology is a more environmentally friendly alternative to traditional cleaning methods that use harsh chemicals and solvents. By using laser technology, industrial companies can reduce their carbon footprint and minimize waste generation.

4. Increased adoption in various industries: Laser cleaning technology is being adopted across a wide range of industries, including automotive, aerospace, electronics, and manufacturing. As more companies recognize the benefits of laser cleaning, the demand for this technology is expected to continue to grow.

5. Development of portable laser cleaning systems: Portable laser cleaning systems are being developed to provide flexibility and mobility in industrial cleaning applications. These compact systems can be easily transported to different locations within a facility, making them ideal for cleaning large or hard-to-reach surfaces.

Overall, looks bright, with continued advancements in technology and increasing adoption across various industries. As companies strive to improve efficiency, reduce costs, and minimize environmental impact, laser cleaning technology is poised to play a key role in achieving these goals.

#laser #cleaning #technology #industrial #sector

Keywords: laser cleaning, industrial sector, technology, automation, sustainability, efficiency

Long-tail phrases: laser cleaning technology in manufacturing, benefits of laser cleaning in aerospace industry, future trends in industrial laser cleaning technology.

Case studies of improved product quality due to laser cleaning

Case Study 1: Automotive Industry

In the automotive industry, laser cleaning has been used to remove paint, rust, and other contaminants from car parts. By using laser technology, manufacturers have been able to achieve a higher level of cleanliness and precision, resulting in improved product quality and performance. This has led to a reduction in defects and an increase in customer satisfaction.

Case Study 2: Electronics Manufacturing

Electronics manufacturers have also benefited from laser cleaning technology. By removing residues and oxides from circuit boards and components, companies have been able to improve the reliability and longevity of their products. This has resulted in fewer malfunctions and returns, ultimately leading to cost savings and a stronger reputation in the market.

Case Study 3: Aerospace Industry

In the aerospace industry, laser cleaning has been used to remove contaminants from critical components such as turbine blades and engine parts. By ensuring that these parts are free from debris and residues, manufacturers have been able to enhance the safety and performance of their products. This has been particularly important in the aerospace industry, where even small defects can have catastrophic consequences.

Case Study 4: Medical Device Manufacturing

Medical device manufacturers have also turned to laser cleaning to improve the quality of their products. By removing contaminants from surgical instruments and implants, companies have been able to reduce the risk of infections and complications for patients. This has not only improved patient outcomes but has also enhanced the reputation of these manufacturers in the healthcare industry.

Conclusion

Overall, the case studies discussed above demonstrate the significant impact that laser cleaning can have on product quality across a range of industries. By using this advanced technology, manufacturers have been able to achieve higher levels of cleanliness, precision, and reliability in their products. This has not only led to cost savings and improved customer satisfaction but has also helped to ensure the safety and effectiveness of these products in their respective markets.

- improved product quality

- laser cleaning technology

- manufacturing industry

- contaminant removal

- customer satisfaction

- reduction in defects

- cost savings

- enhanced reputation

- improved patient outcomes

- increased reliability

#productquality #lasercleaning #manufacturing #reliability #customer satisfaction

The environmental impact of using laser cleaning technology

Energy consumption

One of the main environmental impacts of using laser cleaning technology is the energy consumption. Laser cleaning machines require a significant amount of electricity to operate, which can contribute to greenhouse gas emissions and other forms of pollution. However, compared to traditional cleaning methods that rely on chemicals and abrasive materials, laser cleaning technology is generally more energy-efficient.

Waste generation

Another environmental impact of laser cleaning technology is the generation of waste. While laser cleaning does not produce as much waste as traditional cleaning methods, there is still some waste generated in the form of vaporized contaminants. It is important to properly dispose of this waste to prevent any negative effects on the environment.

Water usage

Unlike traditional cleaning methods that often require the use of water, laser cleaning technology is a dry process that does not use any water. This can help conserve water resources and reduce the environmental impact of cleaning operations. Additionally, the lack of water usage means that there is no wastewater generated, which can be a source of pollution if not properly treated.

Conclusion

Overall, the environmental impact of using laser cleaning technology is relatively low compared to traditional cleaning methods. While there are some concerns regarding energy consumption and waste generation, the benefits of laser cleaning technology in terms of efficiency and precision make it a more sustainable option for many applications.

| Environmental Impact | Concern |

|---|---|

| Energy consumption | Greenhouse gas emissions |

| Waste generation | Vaporized contaminants |

| Water usage | Conservation of water resources |

#environment #laser #cleaning #technology #energy #waste #water #conservation

long tail keywords: environmental impact of laser cleaning technology, sustainable cleaning methods, energy-efficient cleaning technology, waste reduction in cleaning operations

The impact of laser cleaning on reducing waste and environmental footprint

Reducing Waste

One of the key benefits of laser cleaning is its ability to reduce waste. Traditional cleaning methods often involve the use of harsh chemicals and abrasive materials that can generate a significant amount of waste. In contrast, laser cleaning is a non-contact process that does not produce any secondary waste. This means that less material is used and less waste is generated, making it a more sustainable option for cleaning and maintenance.

Environmental Footprint

Another important aspect of laser cleaning is its impact on the environment. By eliminating the need for harmful chemicals and reducing waste, laser cleaning helps to minimize the environmental footprint of cleaning activities. This can have a positive effect on air and water quality, as well as overall ecosystem health. Additionally, the energy efficiency of laser cleaning technology further reduces its environmental impact, making it a more sustainable choice for cleaning applications.

Conclusion

In conclusion, laser cleaning has the potential to significantly reduce waste and environmental footprint in cleaning and maintenance activities. By using high-powered lasers to remove contaminants from surfaces, laser cleaning offers a more efficient and environmentally friendly alternative to traditional cleaning methods. As technology continues to advance, laser cleaning is likely to play an increasingly important role in promoting sustainability and protecting the environment.

- laser cleaning

- waste reduction

- environmental footprint

- sustainability

- cleaning technology

- cutting-edge technology

- non-contact process

- energy efficiency

- ecosystem health

- promoting sustainability

#laser #cleaning #waste #reduction #environmental #footprint #sustainability #technology #ecosystem #health